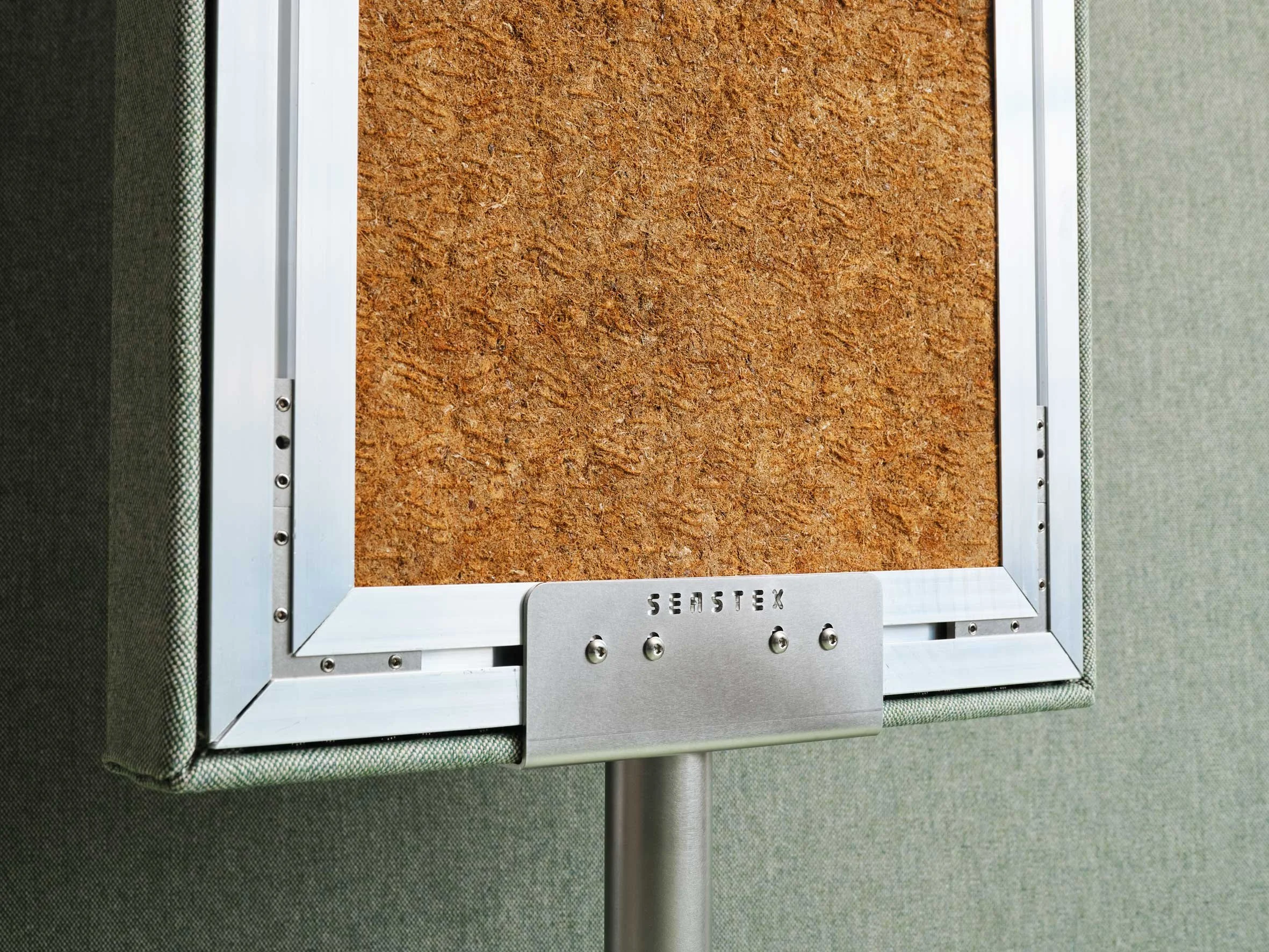

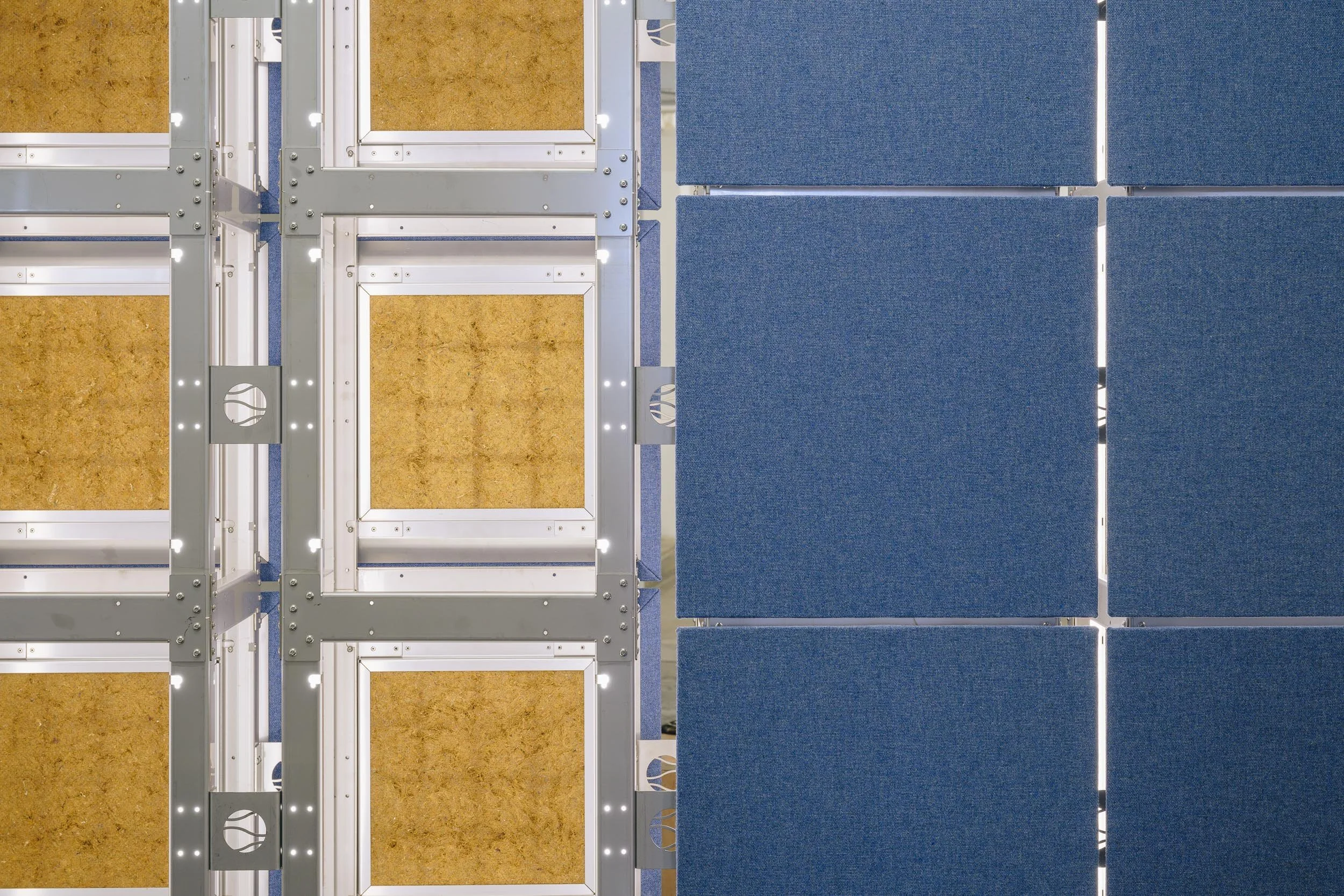

Seastex Ltd, founded in June 2021, has pioneered the development of mussel beard (byssus) products through its novel cleaning and recycling technologies, which are paving the way for innovative, safe, and circular products.

Seastex Ltd, founded in June 2021, has pioneered the development of mussel beard (byssus) products through its novel cleaning and recycling technologies, which are paving the way for innovative, safe, and circular products.